Müller Surfaces is a nationwide, commercial surface installation company based in Charlotte, NC. We work in a variety of industries and are proud to service all 48 contiguous states. We self-perform all of our projects. That allows us to control the quality of work produced and meet remarkably high standards.

We incorporate a wide range of surface installation systems including ceramic tiles, natural stone, mosaic, vibrated floor tile systems, carpet, epoxy, and polished concrete.

Hex Tile. Our is the most innovative solution engineered for the most demanding processing environments. Antimicrobial design, chemical, and temperature resistant. Keep reading »

Red Brick Dairy Tile. Our long-lasting floor sytem that is designed for food processing and dairy plants. Thermal stability, impact and abrasion resistant. Keep reading »

Epoxy. Is a poured in place, durable floor system that can be used across a broad spectrum of industries. Epoxy coating is chemically resistant, durable, and a low maintenance product. Quick installation means less production shutdown and slippage. Keep reading »

Urethane. Urethane mortar flooring is a resinous flooring that like epoxy and MMA flooring is an applied concrete coating. Similar to epoxy and MMA flooring, urethane mortar, also known as urethane concrete or cementitious urethane, produces a seamless resinous flooring solution. Keep reading »

MMA. Methyl Methacrylate (MMA) flooring like epoxy flooring provides a seamless, resinous flooring solution that mimic the epoxy flooring benefits but under harsher enviromental conditions. Keep reading »

Tile is known for its versatility, adaptability, and design flexibility. The wide array of options available when looking at selection of material, color, size (from mosaic to plank or large format) and installation patterns give you seemingly infinite options to customize your project.

Ceramic tile flooring is easy to clean and easy to maintain.

A classic and durable option, tile is not only beautiful but is often the most economical option for long-term installations as well. Whether a traditional or modern look is desired, limitless style options mean that nearly any vision is possible. An additional combination of Eco-friendliness and minimal maintenance really make tile a stand-out option for any installation.

start a project

From adding an element of design to a room to bringing a full artistic vision to life, mosaic tile and tiling is used to create beautiful, intricate designs to any room or building. While mosaic tiles are typically made from one material a mosaic wall, floor, or ceiling can often be a mixture of a variety of tiles such as travertine, glass, stone, porcelain, and more.

start a project

Beautiful and durable, ceramic tiles are environmentally friendly, economical, low maintenance, allergen reducing, and easily repairable. Ceramic tiles are manufactured using natural, water-resistant materials making them a natural, high-quality addition to any space from backsplashes to bathrooms to walls and foyers.

start a project

Porcelain. While similar to ceramic tiles, porcelain tile is typically a harder but more brittle tile. Choosing between the two is often a choice of taste.

Glass. Most often used for decorative and artistic mosaics, glass tiles are used both indoors as well as outdoors.

start a projectThis durable and attractive option is also environmentally friendly. Natural stone is great value due to its uniqueness and low maintenance. With numerous choices available, natural stone can be an excellent choice for many different projects.

Epoxy. Is a poured in place, durable floor system that can be used across a broad spectrum of industries. Epoxy coating is chemically resistant, durable, and a low maintenance product. Quick installation means less production shutdown and slippage. It's temperature, impact, and even fire resistant, making it a great safety choice. Available in an array of colors and patterns to fit nearly any style, epoxy is also a green choice due to its small material usage.

Click the bold links below to view Müller Surfaces resinous flooring brochure and color options.

Resinous Flooring Brochure Vinyl Color Chart

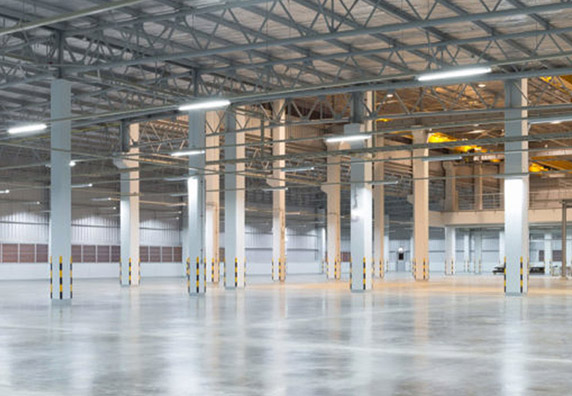

Polished concrete takes concrete from its natural state (a porous product that is susceptible to dusting, spalling, and efflorescence that is difficult to maintain) and locks it up, sealing the concrete. This seal helps the concrete fight penetration by liquid contaminants such as oil and water. It makes the floor dustproof and more aesthetically pleasing. Reduced maintenance and a lower-cost life cycle also make polished concrete an attractive choice in the right industry. Our team moves through a multi-step process of concrete floor preparation, diamond grinding, staining, polishing, sealing and burnishing to achieve your desired outcome.

Polished and stained concrete flooring is a fashionable, economical flooring design process. Easy to maintain floor with mirror like shine, it combines the luxurious appeal of high-end stone with the durability of concrete. With a wide variety of concrete stain colors to choose from, and multiple levels of potential polished sheen, your stained and polished concrete flooring is sure to stand out. It contains no volatile organic compounds (VOCs) so is an environmentally friendly option that is tough enough to withstand anything from foot traffic to forklift trucks.

start a project

Sealed concrete is an economical solution that allows you to protect your concrete slab without all of the steps required in polishing. The level of finish will depend on the condition of the concrete as well as the customers’ expectations. A seal is created by densifying the concrete, which hardens and dust proofs the concrete surface by creating a chemical reaction with the free lime in the concrete.

start a projectEnsuring that every step of the installation is done correctly, starts with a quality substrate to work from. Whether working on a new construction site or a renovation project, we have the tools to make sure the job is done right from the ground up.

Not many people know Müller Corporation is the only company in the United States to use screed pumps. These machines deliver a high quality consistent mudbed mix in a very short time.

The video shared from BMS Bau-Maschinen-Service AG shows how the screed pump works. It is amazing how these pumps will reach up to 60 floors

start a project

When required, leveling the floor surface is the final step in preparing your subfloor for a new flooring installation.

It creates the final flat surface on which we install our flooring systems. It can also be used to pitch a floor toward a drain or patch inconsistencies.

Creating a level surface for flooring installation helps prevent future levelness and bonding issues.

start a project

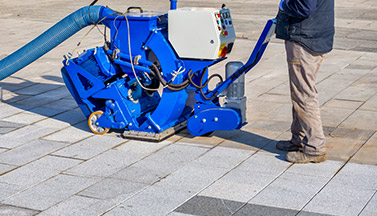

When required, we have the tools and expertise to demolish and remove any existing floor coverings.

Our machines enable us to remove all types of flooring systems including carpet, tile, rubber, VCT, LVT, wood, epoxy, MMA and urethane mortar. They save an enormous amount of labor time on demolition, helping to keep your job on schedule.

start a project

Shot blasting can be a very important step in preparing the surface for a new floor, as it can remove old floor coatings and the contaminants within the top surface layer, or the substrate is heavily damaged.

We manage a fleet of shot blasting machines and a trained team of experienced flooring professionals.

start a project

Many floor coverings cannot be installed over substrate that are holding a certain level of moisture. Our team can test the substrate to determine if a moisture barrier is required.

start a projectThe channel in the floor is a natural break in the overall structure of the floor and as such has the potential to fail if not installed correctly mainly due to the constant wear and tear of forklift trucks traveling over them every day.

Designed and built to meet expectations, our drainage systems use the best quality stainless steel which ensures a long and hygienic service life and provides a cost-effective drainage solution.

ESD floors are designed to protect electronics from damage caused by static electricity. Without ESD protection, electrostatic sensitive devices can be damaged or destroyed, and in places with explosive atmospheres and substances, fire and explosions can occur. ESD floors are especially important in industries where electronic components or volatile chemicals are involved, as static electricity can result in significant damage, injury, and financial loss.

We have the best solution for each industry. Discover it now and let's work together!

| Solutions | Food & beverage | Retail | Pharmaceutical, Medical & Healthcare | Commercial Showrooms Hospitality Offices | Public Buildings Univ & Schools Airports | General Contractors | Residential |

|---|---|---|---|---|---|---|---|

| know more | know more | know more | know more | know more | know more | know more | |

Chemical Resistant Floor SystemTile • Hex Tile • Red Brick Dairy Tile |

|

|

|

|

|

|

|

ResinousEpoxy • Urethane • MMA |

|

|

|

|

|

|

|

ConcretePolished • Sealed • Stained |

|

|

|

|

|

|

|

Traditional InstallationTile • Ceramic • Porcelain • Mosaic • Glass |

|

|

|

|

|

|

|

Natural Stone |

|

|

|

|

|

|

|

Floor PreparationScreed Pumping • Leveling & Screeding Removal • Restoration • Grinding • Testing Moisture Mitigation |

|

|

|

|

|

|

|

Drainage Technology |

|

|

|

|

|

|

|

From a visionary concept to a finished building, it takes a range of people to complete a project. Whether working with the business owner or another trade worker on the job site, Müller Surfaces strives to bring solid communication, respect, and appreciation to every project stakeholder. This means that we train our staff to be flexible, adaptable, and professional to everyone, on and off the job-site.

start a projectThe General Contractor is our main line of communication for most projects. Nearly all communication, decisions, and actions tend to flow through the GC.

While we often receive architectural direction through the General Contractor, we are also happy to work directly with Architects and Designers at any time throughout the duration of a project.

Some owners are extremely hands-on, whilst others prefer to entrust expectations to other capable hands. We are happy to work with both.

Our employees strive to communicate with other trades on-site, ensuring everyone has access to complete their work in an effort to complete projects on time.

Construction as a business is loaded with challenges. Hiring the right people is essential to success. We believe that being professional, adaptable, and dependable for our clients and by offering top-notch, quality work, using highly trained installers consistently for our clients, sets us apart and makes us the right people.

All our highly skilled installers have gone through vigorous training based on the European model, resulting in exceptional craftsmanship.

Our Project Management team makes preconstruction visits to each jobsite and maintains ongoing communication with the crew to develop a staging and phasing plan, control costs, maintain quality, and increase efficiency.

Over the past decade we have had the privilege of working with companies in a very broad range of industries, including retail, commercial, automotive, food and beverage.

Müller Surfaces currently has over 100 employees, including field-based tile installers and support staff in our office in Charlotte.

We work seamlessly with architects, designers, contractors, and business owners to deliver superior results to every project that bears the Müller name. How can we help you?

Epoxy is a poured in place, durable floor system that can be used across a broad spectrum of industries. Epoxy coating is chemically resistant, durable, and a low maintenance product. Quick installation means less production shutdown and slippage. It's temperature, impact, and even fire resistant, making it a great safety choice. Available in an array of colors and patterns to fit nearly any style, epoxy is also a green choice due to its small material usage.

start a project

Urethane mortar flooring is a resinous flooring that like epoxy and MMA flooring is an applied concrete coating. Similar to epoxy and MMA flooring, urethane mortar, also known as urethane concrete or cementitious urethane, produces a seamless resinous flooring solution.

Urethane mortar coating provides a nonporous, easily cleanable surface that discourages bacteria and microbial growth. It works particularly well in areas that experience extreme temperature fluctuations or that must stay either cold or hot for long periods of time like refrigerated areas, freezer areas, or hot food processing areas. Because its thermal coefficient is similar to that of concrete, it manages thermal shock with higher degrees of stability and can withstand temperatures of up to 250°F. It is non-toxic and low VOC, making it nicely suited for food processing, clean rooms, or other areas where liquid containment and harsh temperatures put a strain on flooring surfaces.

start a project

Methyl Methacrylate (MMA) flooring like epoxy flooring provides a seamless, resinous flooring solution that mimic the epoxy flooring benefits but under harsher enviromental conditions

Like epoxy flooring, MMA flooring provides a seamless, resinous flooring solution. Unlike epoxy, Methyl Methacrylate is able to cure at extreme low temperatures in an exceptionally short amount of time – in about an hour, to enable almost immediate use or re-occupation of the space.

MMA flooring is weather resistant, making it an exceptional option for outdoor use, or indoors for pharmaceutical manufacturing, or food and beverage processing facilities like breweries.

MMA flooring is a strong abrasion resistant, chemical resistant, non-slip floor coating that protects floors and holds up to high foot traffic and heavy loads.

It is available in a solid finish, flake flooring (aka chip flooring) or quartz flooring to meet the look and texture your space industrial or commercial space demands. It is available in a variety of colors, chip sizes, and textures.

start a project

Hex Tile Floor System is the most innovative solution engineered for the most demanding processing environments. This floor system integrates a sloping and drainage system ideal for constant hosing and wet environments.

It provides protection from contamination, long-lifspan, and slip resistance. These key features allow the floor to meet hygiene guidelines from the FDA and USDA.

This system is installed using a vibration method that makes full use of the hexagonal tiles’ design to produce a floor with superior impact resistance.

This chemical resistant tile system is ideal for laboratories, breweries, dairies, manufacturing plants, heavy processing areas, bottling plants, and pharmaceutical manufacturers.

Available in a striking array of colors, designs, and textures to complement any environment and offer customized slip resistance options.

start a project

Red Brick Dairy Tile is the ideal solution designed for dairy plants. The products that are manufactured in a dairy plant must be maintained in impeccable and safe conditions every step of the way, from manufacturing to packaging.

This system provides thermal stability, durability, impact and abrasion resistance. These key features allow the floor to withstand a wide variety of corrosive by-products and contaminants such as fats, hot oils, blood, sugar solutions and natural food acids.

This system is installed using a vibration method that makes full use of the tile's design to produce a floor with superior impact resistance.

This tile floor system is designed to fight bacteria, withstand chemical spills, and make it easy to clean the floors. This makes them perfect options for manufacturing areas, packaging areas, and temperature-controlled rooms.

Available in a striking array of colors, designs, and textures to complement any environment and offer customized slip resistance options.

start a project

Food & Beverage. With constantly wet settings, temperature extremes, and frequent high-pressure housing, food & beverage processing facility flooring must withstand serious punishment and are exposed to a wide variety of corrosive by-products and contaminants such as fats, hot oils, blood, sugar solutions and natural food acids

High volume food & beverage processing plants present a unique set of challenges when it comes to facility flooring

We deliver FDA- and USDA flooring solutions:

To maintain cleanliness, manage the risk of uncontrolled bacterial growth, the flooring surfaces used in food and beverage production facilities must adhere to strict health and safety guidelines mandated by the United States Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA).

Each industry sector has specific flooring needs:

Retail. Floors that are exceptionally durable, easy to clean, safe and skid-resistant—all while offering updated decor and design flexibility are the stuff that every shopping mall, retail store and office complex manager dreams of.

We offers a complete line of flooring systems that meet the needs of retail environments with panache:

Pharmaceutical, Medical & Healthcare. An clean and sanitary environment is the right solution to ensure the safe, sanitary, germ-free requirements of your work area and it is important to assure durable and resistant surfaces easy to maintain, that provides sanitary levels of cleanliness and also resists moisture, chemicals and other contaminants

Commercial Hospitality Offices - Departament Stores - Grocery Stores - Food Courts - Hotels. Floors are the largest and one of the most essential elements of interior design, when it comes to defining and enhancing the overall look and feel of a retail environment.

We offer a complete line of flooring systems that meet the needs of retail environments with panache: Durable and impact resistant, for foot and cart traffic, attractive, custom designs and patterns available, moisture and chemical resistant, endless colors, textures and styles, to match corporate brand identity and fast installation

Public Buildings - Universities & Schools - Airports. From primary schools to universities, educational institution flooring endures constant traffic.

We offer a complete line of flooring systems that meet the needs of this kind of building need: Resistant, easy to clean and fast installation. Every system could be adapted to your needs and budget.

start a project

General Contractors. The General Contractor is our main line of communication for most projects. Nearly all communication, decisions, and actions tend to flow through the GC.

While we often receive architectural direction through the General Contractor, we are also happy to work directly with Architects and Designers at any time throughout the duration of a project.

start a project

Residential. For residential renovations the General Contractor is our main line of communication for most projects. Nearly all communication, decisions, and actions tend to flow through the GC.

While we often receive architectural direction through the General Contractor, we are also happy to work directly with Architects and Designers at any time throughout the duration of a project.

start a project